Common Symptoms that Indicate an Underlying Tooling Problem

If you are experiencing any of the following, you may have a tooling problem:

- Increased tooling costs

- Vibration and chatter

- Excessive harmonics on the mill

- Lengthy set up times

- Shortened tool life

- Poor tolerances

- The need for excessive polishing and finishing time

- Run-out

- Tool rigidity issues

- Non-repeatability

- Costly downtime

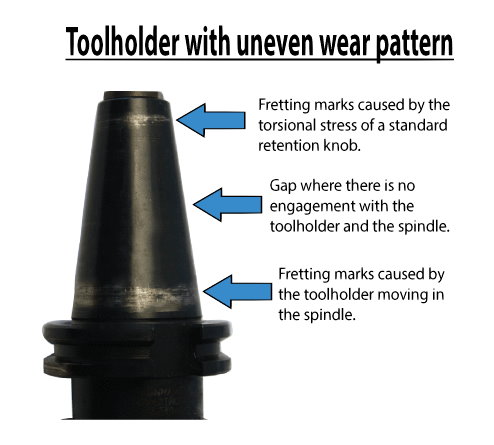

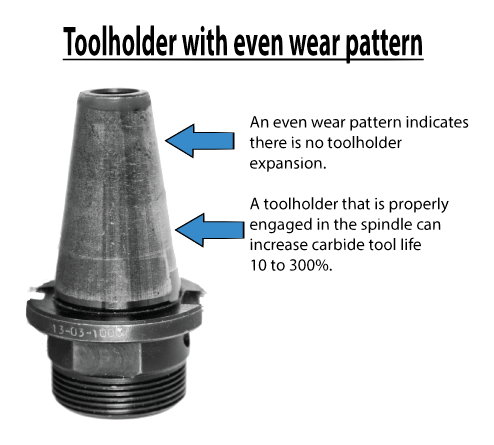

Toolholder expansion can quite often be identified simply by looking at the wear patterns on the toolholder itself. Wear marks at the small end, and at the gauge line, with no wear in between are a clear indication of toolholder expansion.